Graphene thin film transfer from copper sheet to PET substrate using UV and thermal release tapes

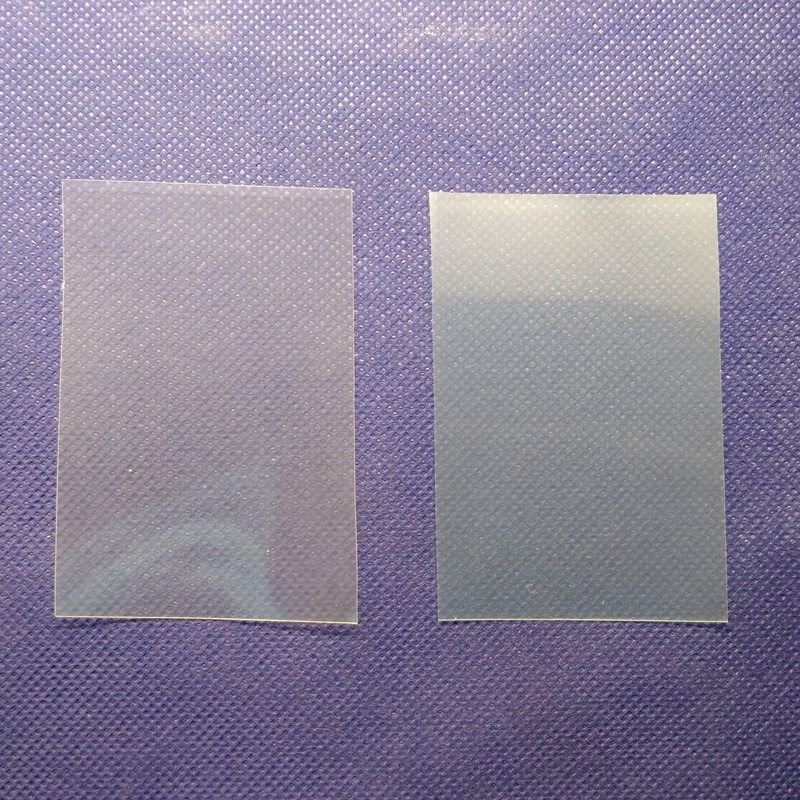

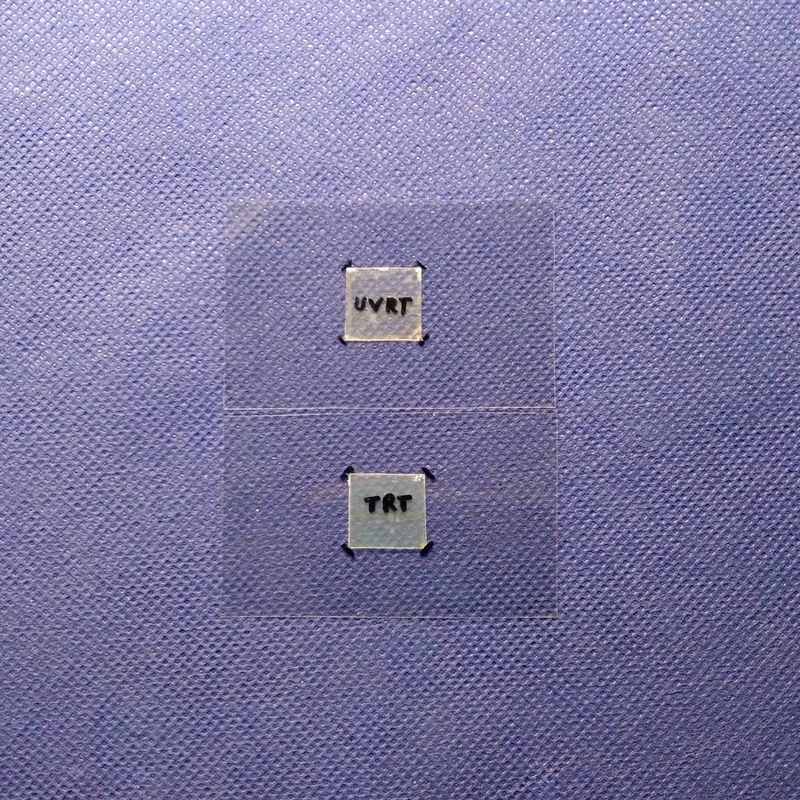

Release tapes kind of ordinary tapes (sellotapes) which lose the adhesivity after exposed to enough heat or UV light irradiation. In the below image the heat release tape (hereafter called TRT) can be observed on the right and the UV release tape (UVRT) on the left.

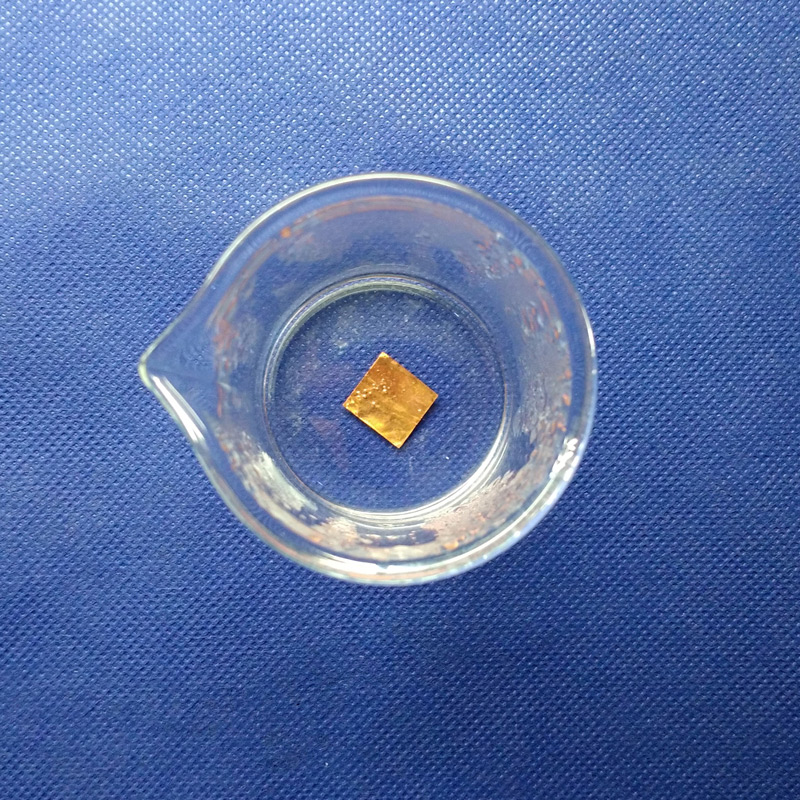

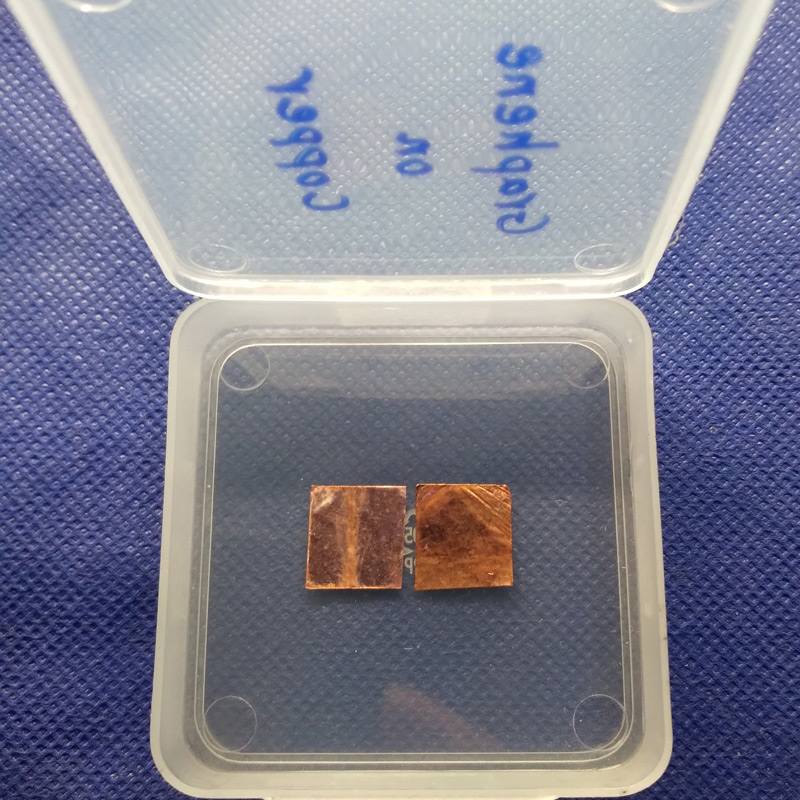

Single layer graphene mono layer deposited on the copper foil was readily purchased from the Suzhou Tanfeng Graphene Technology Co. Ltd. The foil which carries the film on both sides was immersed in the beaker replete with boiling de-ionized water at nearly 100 degrees centigrade for 5 hours. After the end of period, the approximately lustrous copper foil was turned into a matte color which is attributed to the oxidation of copper in the boiling water which is observable below.

By copper oxidizing, oxygen atoms were introduced on surface of the copper foil and as a result the bonds between the graphene layer and the below substrate were loosened. Therefore, the graphene can be peeled off the foil more easily. Thermal release tape on the one side of foil and UV release tape on the other side was adhered. Afterwards, it was rolled by hand roller several times to ensure the sufficient adhesivity and air bubble removal.

The both tapes were peeled off meticulously from the copper surface and adhered to a piece of PET substrate separately. This PET sample can be seen below.

By using the hand roller once more, the release tapes were rolled several times to stick to the PET substrate.

In order to obliterate the adhesivity of the thermal release tape, the PET substrate was heated by 170 degrees centigrade hot air flow for 3 minutes. In this stage, the release tape was observed to peel off by discoloration and supposedly the adhered graphene layer was transferred to the PET substrate. As for the other side of the foil which was covered by the UV release tape, it was exposed to the direct UV bed exposure for 24 minutes. In order to err on the side of caution, the foil was flipped every 6 minutes to ensure perfect adhesivity elimination. At the end, the UV release tape was removed using a pair of tweezers. Both substrates were supposedly covered by a graphene thin film after releasing the tapes.

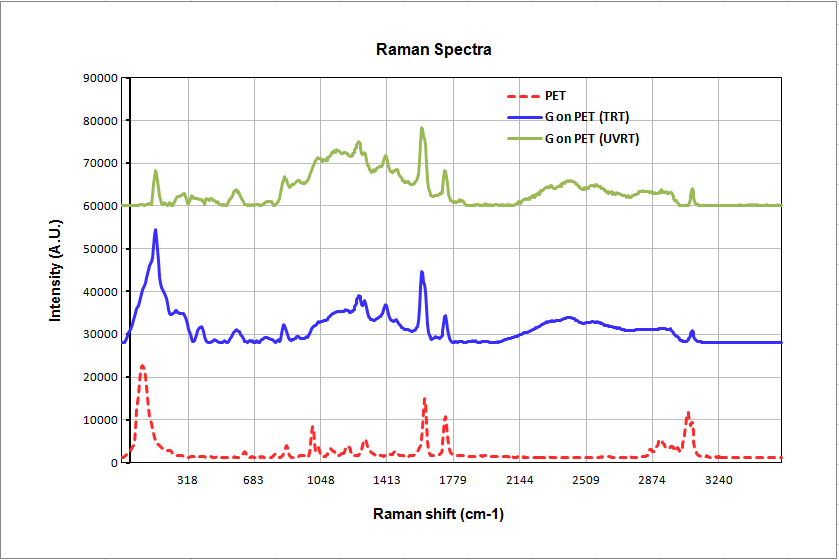

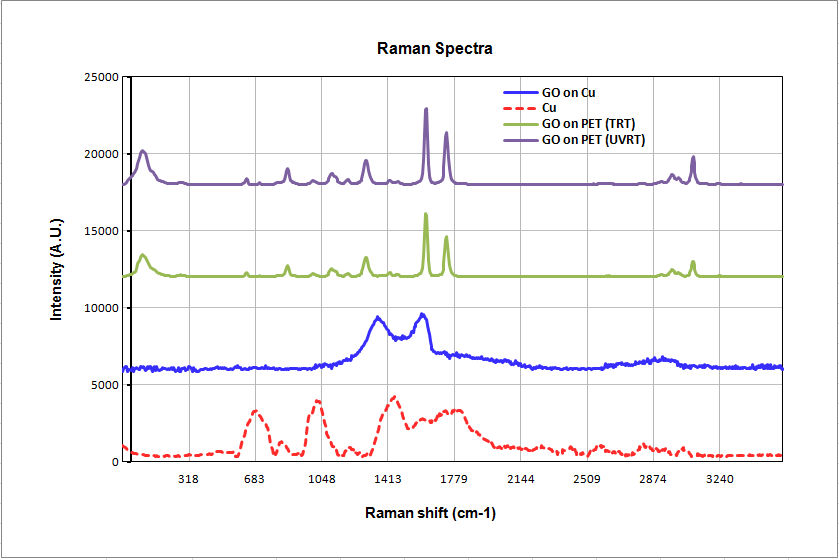

The PET samples supposedly to bear the graphene thin film were analyzed by Raman analysis to check whether the graphene film was transferred from the copper foil.

At the second part of experiment, a GO layer was deposited on the copper foil utilizing the electrophoresis from aqueous dispersion of GO in de-ionized water. In order to make the electrophoresis bath, 2 cc GO aqueous dispersion was poured into a 100 cc beaker and diluted by adding 60 cc of DI water. A silver electrode was connected to the negative pole of a power supply and a copper substrate which was degreased and rinsed using isopropyl alcohol and acetone was place facing the silver electrode at the distance of 16mm connected to the positive pole. By applying 17V DC between two electrodes and for a period of 5 minutes at the temperature of 28 degrees centigrade, the GO was precipitated on the copper foil. The deposited foil was rinsed by DI water and aerated to be desiccated.