ITO Polymer Sheets Etching Experience

Indium tin oxide (ITO) coated on glass substrate or translucent polymer like PET has been in market for years. Thin layer of ITO is both transparent and electrical conductive, so it has found its way to optics and electronics. As an example the anti-frost, airplane windshields glasses are deposited with a very thin layer of ITO. By passing the current, heat dissipation can defrost the snow or ice. Another common application is LCD manufacturing.

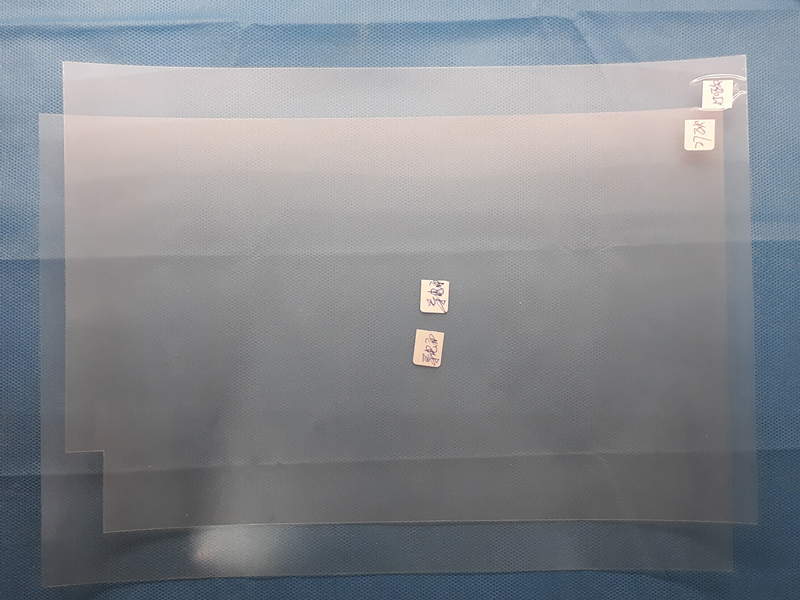

There are so many types of it in market and it is sold by its Ohms/square characteristics (like integrated circuits layers) and also its transparency. I got several sheets for free as samples from some Chinese companies to test the quality. They are in fact cheap materials as the constituent elements are not pricey. They are generally manufactured by PVD method in vacuum. Here is a picture of A4 sheets of ITO.

I cut a piece off the A4 sheet to work on. There are two protective film on both sides of it which needs carefully to be peeled off the surface. These removed films can be seen on top of polymer coated ITO:

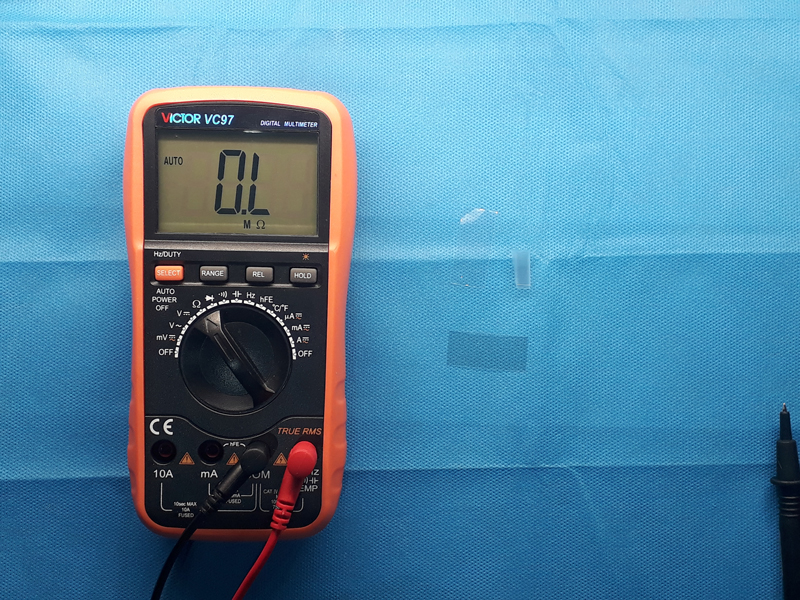

It is seen that the ITO polymer substrate is partially conductive:

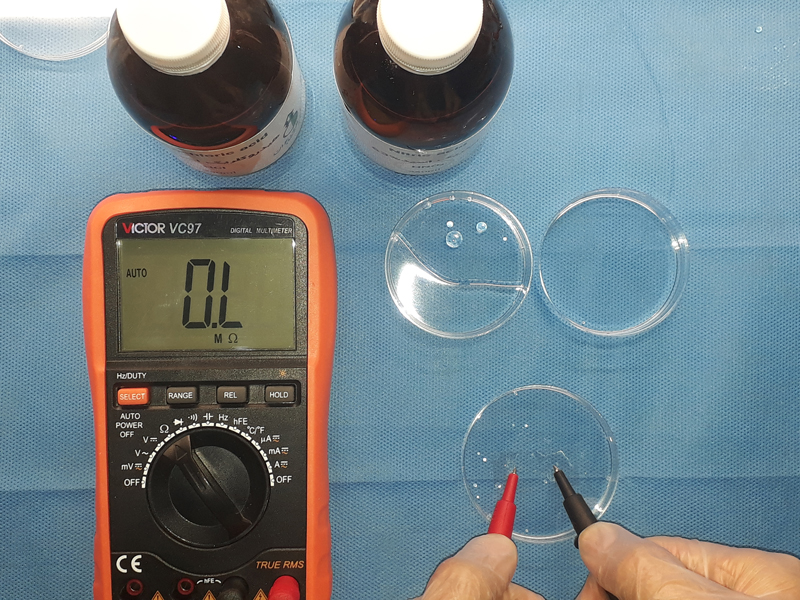

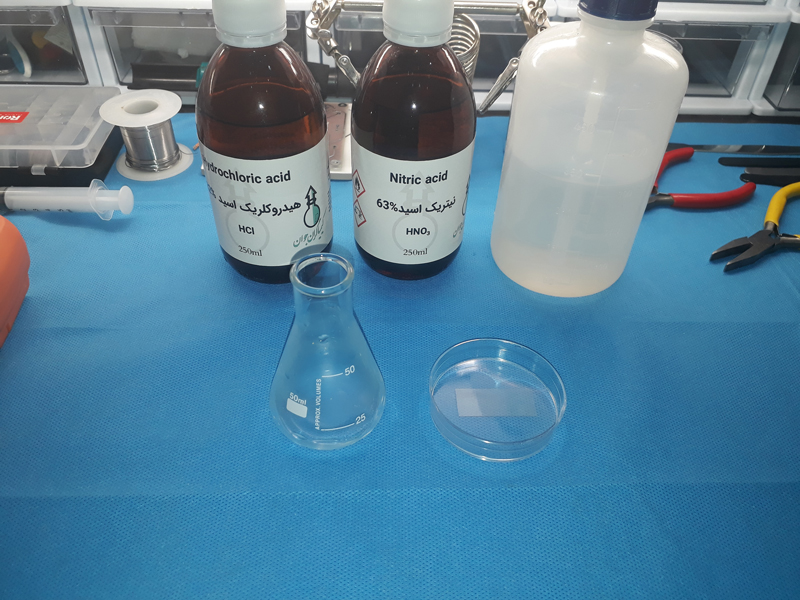

Then I made a solution containing 2 cc HCl, 1 cc water and 0.5 cc HNO3 to form the etchant.

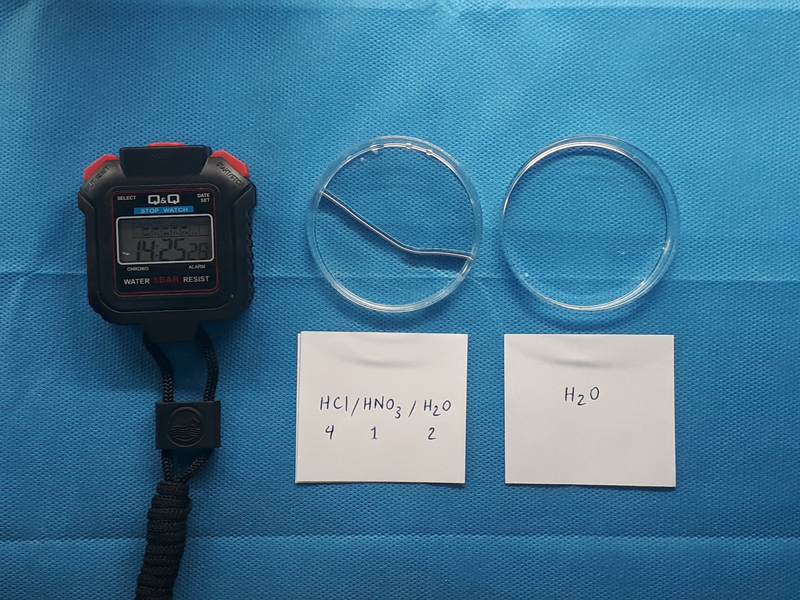

After, I put the substrate into the Petri dish full of the solution and ignited the timer. After about 14 minutes I took it off and rinsed with water, then tested if the etchant have removed the conductive layer of ITO or not.

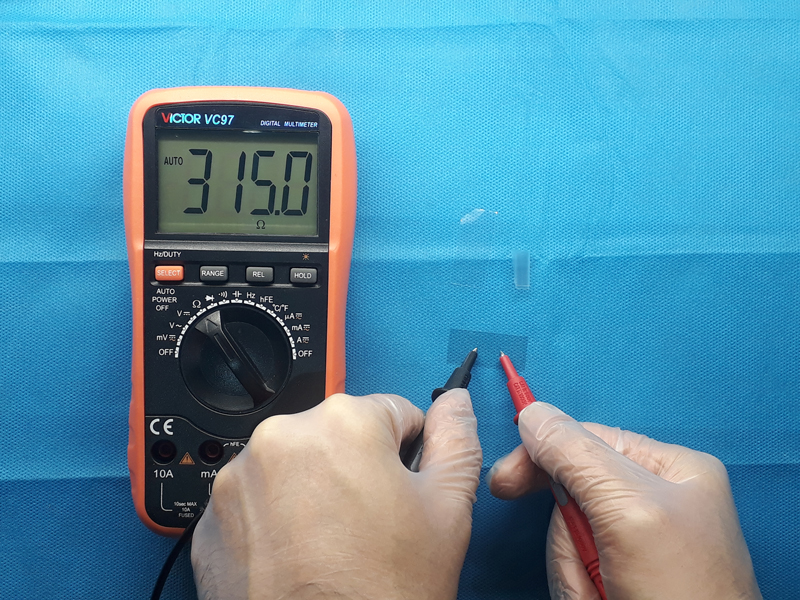

Voila! it is practically gone! So the etchant solution works. No conductive film anymore on the polymer.